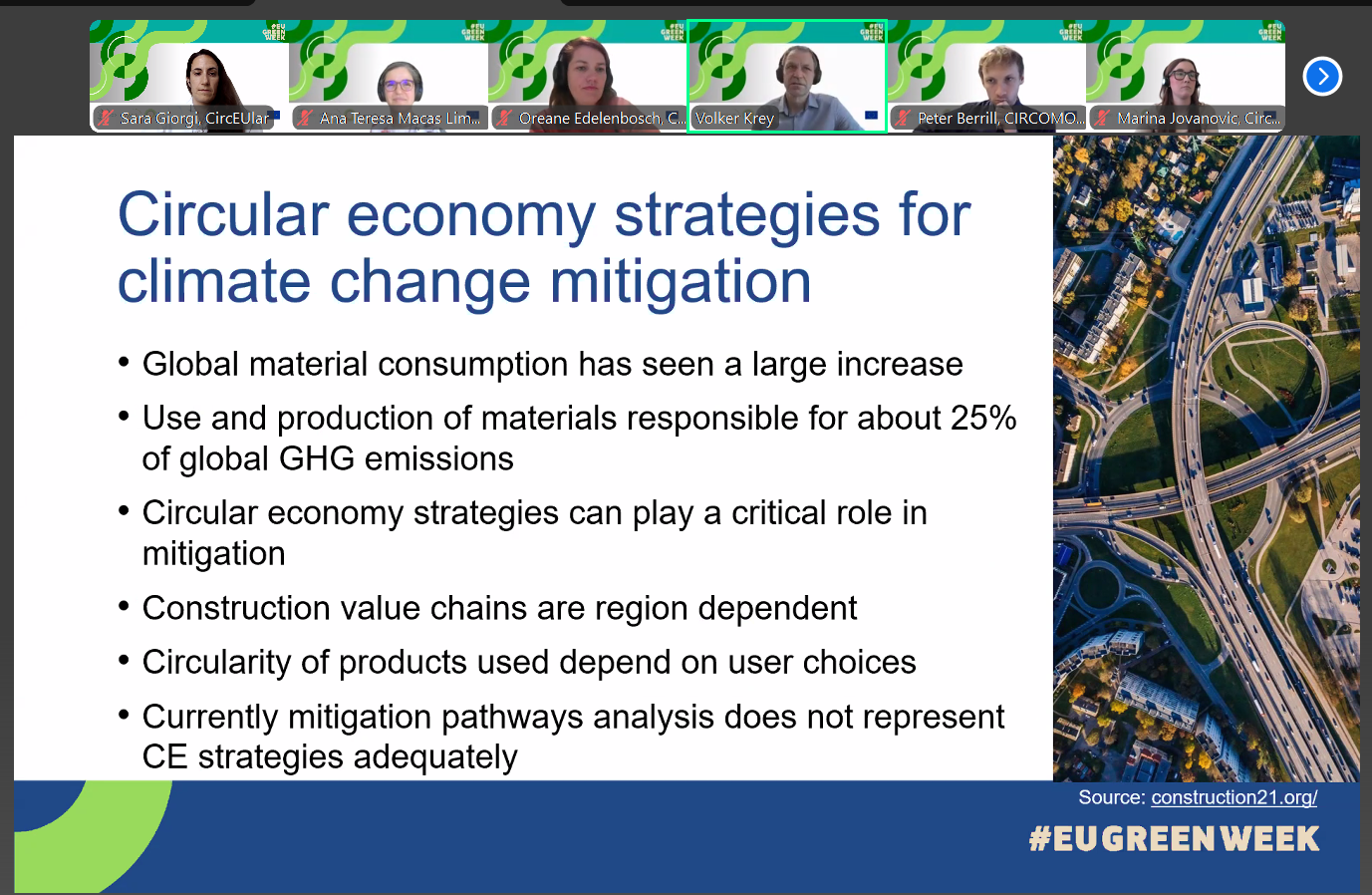

We started off with an overview of why it is important to focus on the built environment – did you know that construction materials used in buildings and transport infrastructure account for around half of GHG emissions from the global material production? We heard about the conceptual framework underpinning all three EU Horizon sister projects: narrow – use less, slow – use longer and close – use again which is an effective way of grouping circular practices in blocks. All three projects also draw from the 10Rs from reuse to recover.

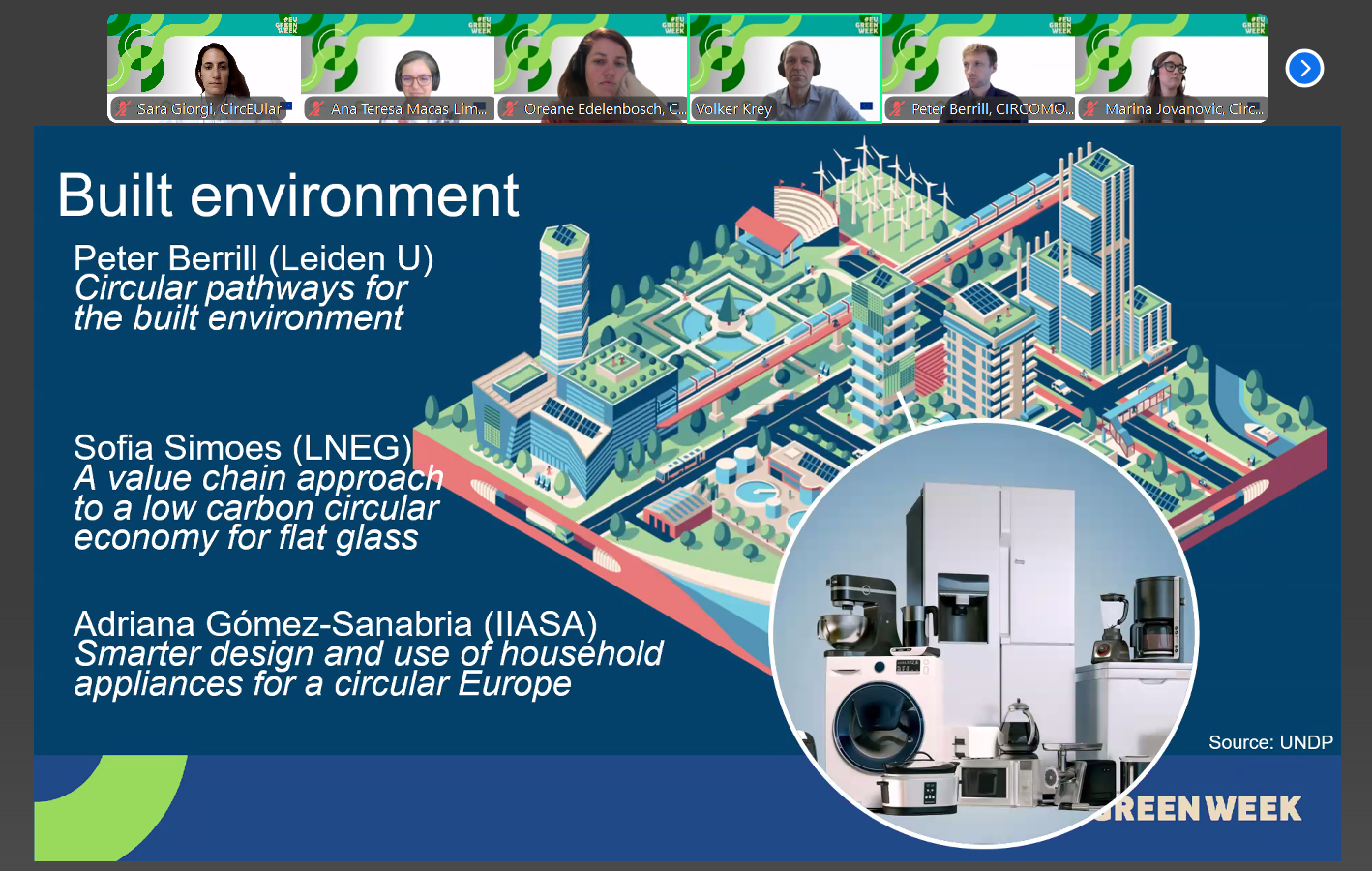

CIRCOMOD’s Peter Berrill started off with a helicopter and systems view of global projections for material use in the built environment along with circular economy targets, assessing how circular strategies can influence material pathways to support climate change mitigation. CO2NSTRUCT’s Sofia Simoes followed by taking us on a deep dive into one of the more carbon intensive construction materials’ value chain: flat glass. To conclude, from CircEUlar, our Adriana Gómez-Sanabria zoomed into what things look like on the inside, specifically how household appliances can and should be used in a more circular future. This journey from the system-wide infrastructure connecting buildings and transport to the construction materials used in buildings to how consumers use household appliances inside buildings enabled participants to get a good holistic understanding of the scale and complexity of the research undertaken.

The session ended with an exchange around different topics including: indicators used for the narrow scenarios, how consumer appetite for narrow circular strategies can be integrated into the models and simulations, how the different scenarios interact with each other – whether they are accumulative or integrative, how trade-offs between using products for longer and advances in energy efficiency in new products are addressed, how implications of material substitutions are approached and how the scale and dimensions of different strategies are accounted for (e.g. using fewer materials in manufacturing a product vs using fewer products).

All in all, we are very pleased to have had the opportunity to share preliminary findings with attendees and look forward to further fruitful collaborations with CIRCOMOD and CO2NSTRUCT as we move into the final year of the project.